As climate change intensifies around the world, it is urgent for students to understand and utilize the principles of sustainable design in their entrepreneurial pursuits. To help faculty create opportunities for students to engage in green design methods, we’ll spotlight key exercises from the Tools for Design and Sustainability course, developed by Dr. Jeremy Faludi, assistant professor of industrial design engineering at Delft University of Technology (TU Delft). We’ll explore several exercises that will help faculty easily introduce sustainable design concepts in their courses.

Innovation and entrepreneurship can help introduce new products and services to the world that can combat climate change. To ensure that new innovations help protect the planet, even if their main function isn’t directly climate-related, innovators need to design with the environment in mind. One way to do this is to incorporate green materials into their product design.

Green materials are materials for manufacturing that have a lower environmental impact than traditional options. A great example is from one of our E-Team Program grantees—Transfoam. They’ve developed a biomanufacturing process that uses engineered microorganisms to convert petroplastics (which are plastic products derived from petroleum) into a biodegradable plastic alternative called PHB; this bioplastic is derived from waste-based raw materials, which replaces environmentally harmful materials in the manufacturing process. Their innovation tackles two problems: removing pollution from conventional plastics in the environment, and producing a sustainable closed-loop alternative.

Waste innovation is an exciting field of environmentally focused innovation, and using greener materials provides some of the most promising solutions for waste issues. In 2020, Dr. Caroline Baillie of the University of San Diego developed a course that tasked students with transforming discarded trash in California’s Tijuana Estuary Canyons into usable products and materials. Using recyclable materials can help mitigate some of the manufacturing sector’s impact on the environment. Industrial manufacturing requires an enormous amount of raw materials and produces at least half of the waste generated in the world each year. Identifying and replacing high-environmental-impact materials with environmentally responsible materials can help student entrepreneurs ensure that their innovations are not causing additional environmental harm and support a shift to greener industrial manufacturing.

Faculty can integrate green materials to teach sustainable design principles to students. One way to start introducing sustainable design methodology is to implement instructional activities such as this greener materials exercise from Dr. Jeremy Faludi’s Tools for Design and Sustainability. Visit the Greener Materials section for additional learning content.

Prioritizing Sustainability at All Stages of the Innovation Cycle

The process of choosing a greener material can be overwhelming. There are a number of factors that need to be considered when selecting the optimal material for a product. Dr. Faludi recommends that sustainable materials should be characterized as:

- Abundant / rapidly renewable

- Less resource-intensive (requires minimal energy or other material to produce)

- Chemically safe and healthy

- Able to have many lives (via recycling, reuse, or composting)

- Socially benevolent

- Financially affordable

- Able to meet relevant laws and regulations

- Durable and long-lasting

- Greening the whole system—with actions that reduce environmental impacts among all the processes involved in manufacturing a product

Similar to our biomimicry mentors exercise, this exercise is designed to provide a level of real life application: task students with finding a green material for their innovation that can replace a material that negatively impacts the environment. Here’s the breakdown:

- Students identify a high-environmental-impact material in their innovation.

- Students search for alternative materials online or through the Finding Greener Materials resource page.

- Once students identify a potential alternative material, they obtain price quotes to evaluate financial feasibility.

Faculty can add an extra spin to the exercise by adding parameters such as limiting students to use only newly invented, locally sourced, natural, waste, or recycled materials. This exercise can help students understand that sustainability can and should be a part of every component of the innovation process.

Sugar-Powered Innovation

As part of a course at Minneapolis College of Art and Design, students Annika Bergen, George Cook, Ellie Cotlar, and Dawn Suite discovered that they could replace the lithium ion batteries in their invention with sugar-based batteries.

As part of a course at Minneapolis College of Art and Design, students Annika Bergen, George Cook, Ellie Cotlar, and Dawn Suite discovered that they could replace the lithium ion batteries in their invention with sugar-based batteries.

The lithium and nickel used in their original battery were not renewable; in addition, disposing of lithium ion batteries causes negative impacts to the environment and to human health, because they contain flammable electrolytes and toxic materials like lead and nickel. The sugar battery uses maltodextrin made from cornstarch and enzymes (proteins that catalyze chemical reactions in living organisms) so it is naturally renewable. Sugar-based batteries are also safer than lithium ion batteries, because they are not flammable or explosive. Finally, at 10% of the cost, the sugar battery is significantly more affordable than lithium ion batteries.

Creating Fabric From the Sea

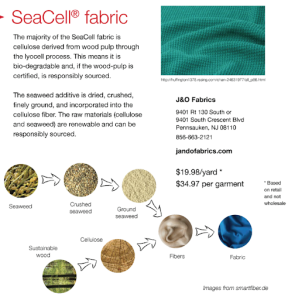

After researching five options, another student team at Minneapolis College of Art and Design, led by Mark Chamberlain, Megan Graham, Natasha Johnston, and Stacy Parker, found that the best alternative for the polyester fabric in their innovation was a cellulose-based fiber, dubbed “SeaCell” by the team.

Polyester is made from petrochemicals that are not biodegradable and require large amounts of water, electricity, and chemicals to produce. Polyester production released about 706 billion kg of greenhouse gasses into the environment in 2015, and every year, between half million and a million tons of microfibers—largely from polyester—end up in our oceans, croplands, food, and drinking water. SeaCell®, on the other hand, is made of crushed brown algae seaweed and cellulose derived from wood pulp, making it biodegradable and easy to responsibly source.

Polyester is made from petrochemicals that are not biodegradable and require large amounts of water, electricity, and chemicals to produce. Polyester production released about 706 billion kg of greenhouse gasses into the environment in 2015, and every year, between half million and a million tons of microfibers—largely from polyester—end up in our oceans, croplands, food, and drinking water. SeaCell®, on the other hand, is made of crushed brown algae seaweed and cellulose derived from wood pulp, making it biodegradable and easy to responsibly source.

Innovation and entrepreneurship will be critical tools in mitigating and reversing the impacts of climate change. The materials we use to manufacture these innovations need to alleviate environmental harm and not cause more environmental harm. This activity and others in the Tools for Design and Sustainability can help faculty introduce sustainable design principles into their classrooms and inspire their students to be more environmentally conscious.

Samuel Yoo, a Program Officer at VentureWell, supports institutions with developing programs involving sustainability-focused science and technology innovation and entrepreneurship. Previously, he researched bioenergy solutions at the Energy & Biosciences Institute, taught STEM disciplines in public schools, and led sustainability initiatives at the University of Illinois Urbana-Champaign.

Samuel Yoo, a Program Officer at VentureWell, supports institutions with developing programs involving sustainability-focused science and technology innovation and entrepreneurship. Previously, he researched bioenergy solutions at the Energy & Biosciences Institute, taught STEM disciplines in public schools, and led sustainability initiatives at the University of Illinois Urbana-Champaign.