circular economy

Content

Goal: Understand design and business strategies to enable closed-loop production, so each end of life becomes a new beginning.

Goal: Understand design and business strategies to enable closed-loop production, so each end of life becomes a new beginning.

Often the best way to reduce material consumption is not to lightweight your product, but to get more service out of it. For example, if a product gets used ten times as much during its lifetime, it uses 1/10th as much material per unit service; by comparison, the best engineer might be lucky to reduce material use 10–30% through lightweighting. This increase in service can happen either by the product having a longer life (being used by the same person for ten times as long), by the product being shared (lasting the same time, but being used by ten times as many people), or a combination of both. This goes by many names–Cradle to Cradle, industrial ecology, and most recently the Circular Economy.

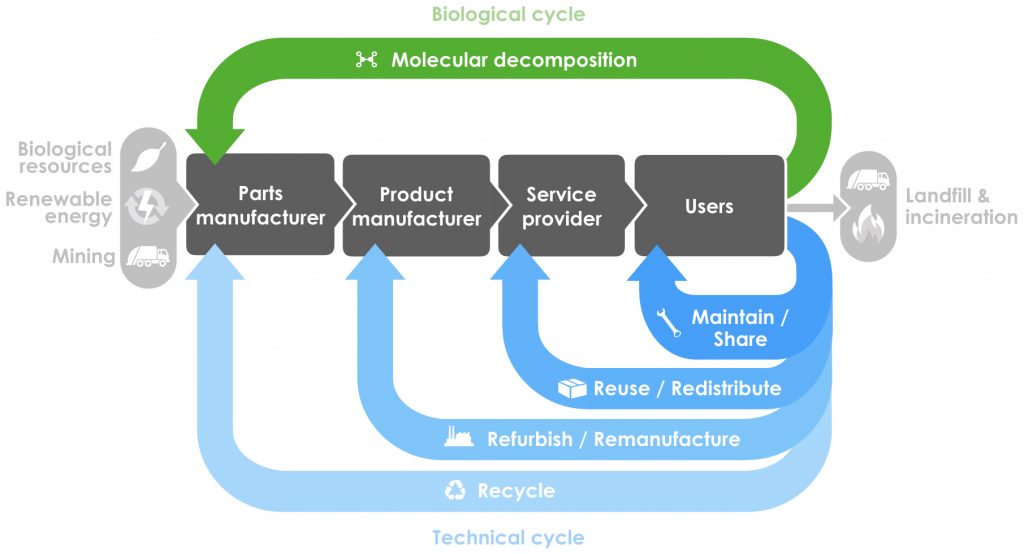

This diagram shows many possible resource loops in a circular economy, fixing the linear “take-make-waste” economy. The tighter the loop, the more resource-efficient it usually is. As defined by Cradle to Cradle, biological nutrients are things that were grown and can become food for other plants or animals (composted or biodegraded). Technical nutrients are anything dug out of the ground that can’t return to biological cycles but can be recycled or otherwise become a resource for making other products. Technical nutrients must all have their own separate recovery loops to avoid contaminating each other, but biological nutrients usually don’t require separation. Biological nutrients can also go through technical cycles of reuse, remanufacturing, etc., to lengthen their service life.

Design for Circular Economy (Design for Lifetime)

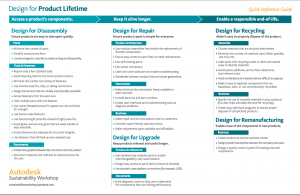

Designing for the circular economy can mean designing for a long life, designing for a good afterlife (disassembly and recycling), or designing for repair and upgrade. See the videos below for details:

Autodesk Sustainability Workshop Introduction to Design for Lifetime

Autodesk Sustainability Workshop Design for Durability

Autodesk Sustainability Workshop Design for Disassembly and Recycling

Autodesk Sustainability Workshop Design for Repair and Upgrade

You can also download the Autodesk Quick Reference Guides on these topics:

Quick Reference Guide–Design for Lifetime | Quick Reference Guide–Design for Durability

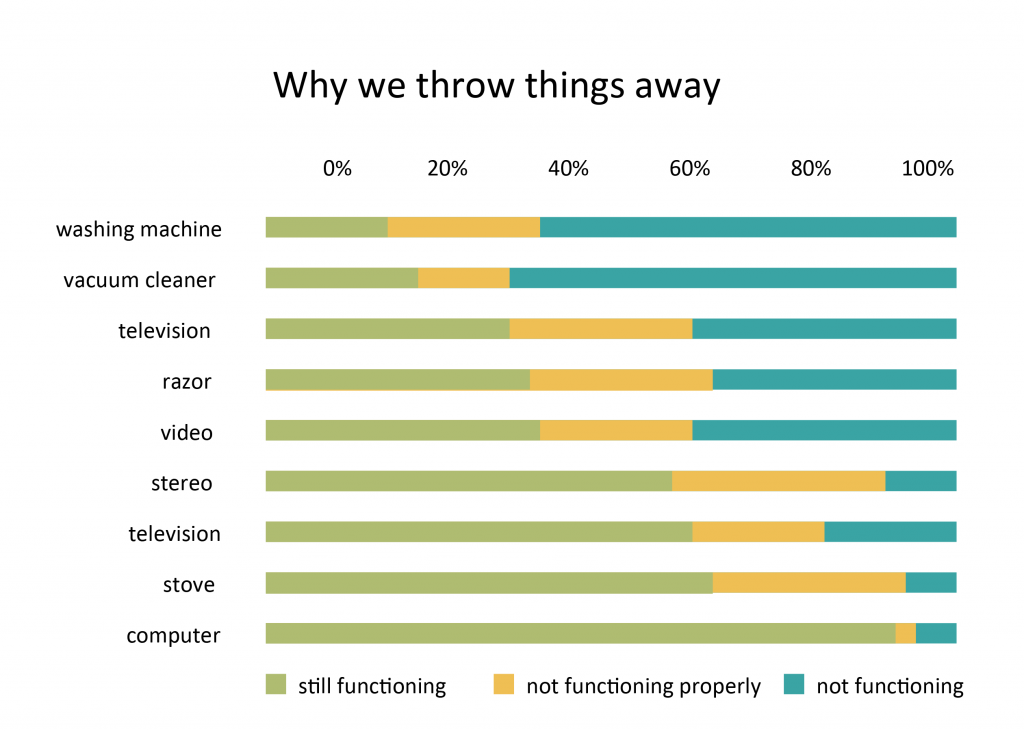

Why we throw things away. Image Source: Eternally Yours Foundation, via Okala Practitioner

Here are more resources on design for lifetime:

- Natural Capitalism (Hawken, Lovins, and Lovins), chapters 4 and 7. These chapters describe manufacturing optimization, the importance of measuring to find opportunities, design for service, and designing for circular material flows.

- Eternally Yours: Time in Design by Ed Van Hinte. This book describes how to design for long life in terms of aesthetics, culture, and flexibility.

- The Maker’s Bill of Rights manifesto by Make magazine. This short list of demands is a good reference for how to design for repair and upgrade.

- Bloom Laptop for Disassembly and Recycling Final Report. This student project from Stanford University is an example of how a laptop can be designed for disassembly, repair, upgrade, and recycling.

Designing for lifetime can be more expensive; one way you can make more money while also saving your customers money is to design for sharing. This changes not just the product design, but the business model.

Business Models for a Circular Economy

Designing for the circular economy requires new business models to make designs viable. How do ten people share the product? When do they pay, how do they get access, etc.? Or if your products last ten times as long, how do you stay in business? You might charge more, or add profitable upgrade, repair, and maintenance services. You might also change the business model: perhaps you own the product instead of the user, and charge subscription fees for use, rather than a one-time purchase every few years. A similar business model also works for sharing the product across many people. If none of these are possible, you might at least use a business model that takes back old products and remanufactures them, or reuses material. Then you can design your products to enable these better lifetimes.

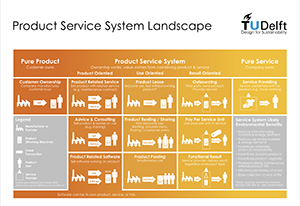

As mentioned above, sharing a product among ten people can reduce its material impacts per person by 90%. Product service systems redesign the product (and, more importantly, its business model) for sharing. There are many ways of doing this; click on the graphic below for a summary.

Product service system landscape. Image credit: Jeremy Faludi, TU Delft; inspired by Tukker 2004.

Designing product service systems is a deep field of study—you can even get a masters degree in it from Blekinge Institute of Technology. Another source of information on product service systems, including barriers to adoption and how to overcome them, is Promoting Innovative Business Models with Environmental Benefits by the EU Commission, especially section 5.2 “Business Rationale” (pp.29-31) and section 7, “Realizing PSS” (pp.39-46).

Barriers to product service systems and how to overcome them, from the EU Commission paper above.

Finally, a more general tool for environmentally and socially responsible entrepreneurship is the Business Sustainability Booster by prof. Marsha Willard of the Presidio Graduate School of business. It is an overlay for the standard Business Model Canvas, presenting sustainability considerations at each step. It is an exploratory tool, not giving you answers, but giving you questions to ask in each section of the business model canvas to help drive sustainability. The video below summarizes it:

This can help drive more holistic and comprehensive sustainability strategies.

All VentureWell Tools for Design and Sustainability content is shareable and usable by CC BY-NC-SA 4.0 license.